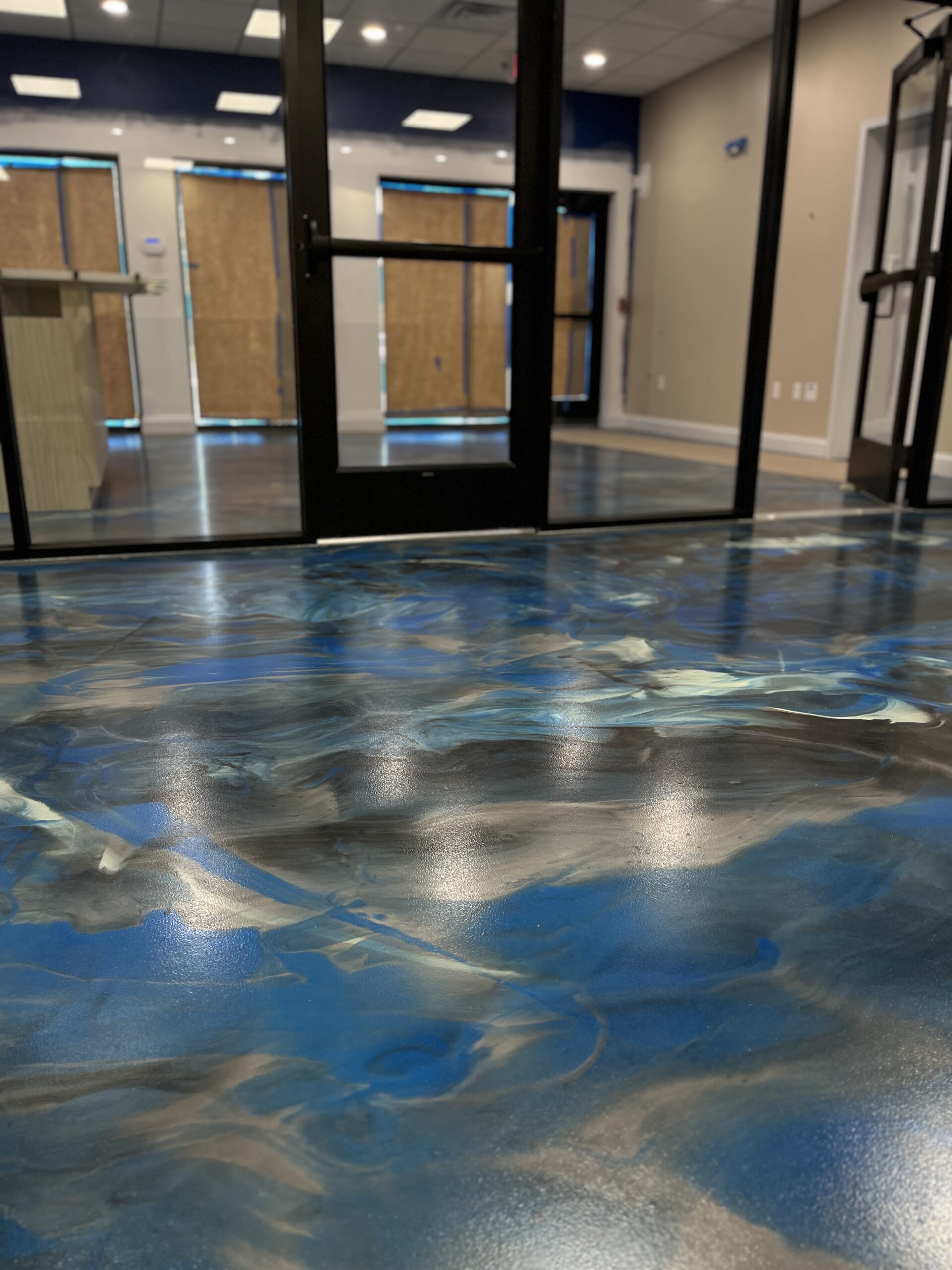

Cannabis Facility Flooring Solutions

Flooring Systems for Grow Rooms, Extraction Labs, and Processing Areas

Black Bear Seamless Flooring works with cannabis growers, processors, and lab operators to install clean, durable, and regulation-ready flooring systems. Our floors meet strict cleanliness standards and withstand the high-humidity, chemical exposure, and heavy foot traffic common in cannabis operations.

Request a site visit