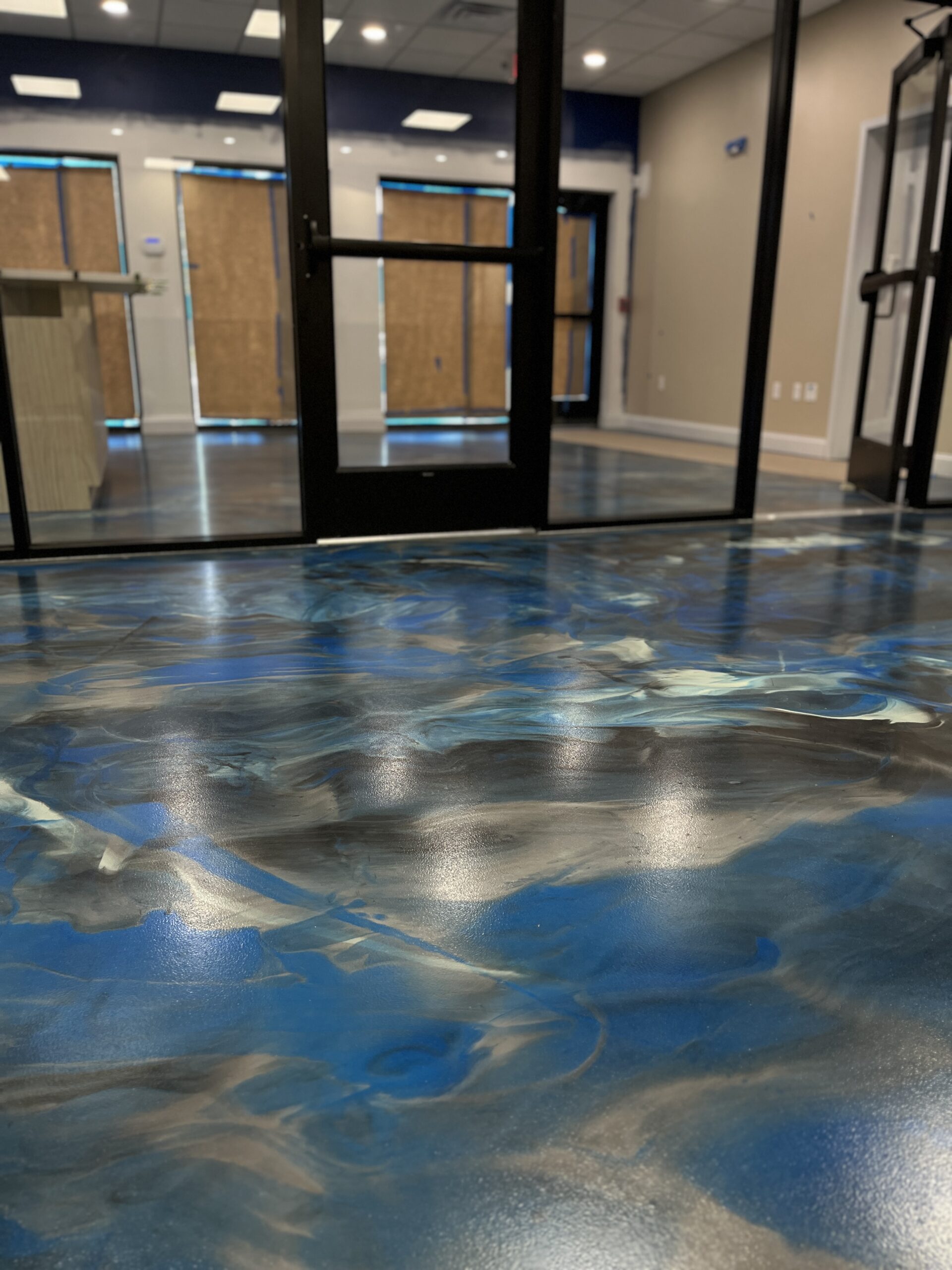

Epoxy Flooring Solutions

Durable, Hygienic, Long-Lasting for Demanding Environments

Black Bear Seamless Flooring installs industrial and commercial epoxy flooring systems designed to meet the unique demands of schools, hospitals, warehouses, laboratories, commercial kitchens, and more. Our expert team customizes each installation to ensure durability, safety, and long‑term value for your facility.

Request a site visit