Northeast’s leading seamless? Call Us Now 978-405-0017

Electrostatic discharge (ESD) is one of the most persistent and costly threats in cleanroom environments. A discharge as small as a few dozen volts can disrupt circuits, degrade microelectronic components or compromise sensitive manufacturing processes. That’s why specialized ESD flooring becomes so critical in these spaces.

ESD flooring plays a central role in controlling these risks by creating a predictable, low-resistance pathway that safely transfers static charges to ground.

So let’s break down the materials designed to control electrical resistance and how conductive and static-dissipative flooring systems work. We’ll also look at how proper ESD flooring helps facilities maintain compliance with industry standards while supporting consistent performance in cleanroom operations.

Electrostatic discharge (ESD) flooring is a purpose-built surface that manages static electricity in environments with sensitive equipment. It prevents static buildup by channeling it straight to the ground.

Made with unique conductive elements, like carbon bits or tiny fibers, the floor pulls static away fast. When the energy reaches the surface, it moves along designated paths and then disperses quietly into the earth.

Installing ESD flooring adds an important layer of protection to daily operations. In labs, cleanrooms and electronics facilities, it helps prevent costly damage and keeps work running smoothly. This is especially important for safeguarding sensitive equipment like circuit boards, medical devices, precision instruments and other high-value electronics.

By incorporating effective grounding systems, facilities can meet industry standards like ANSI/ESD S20.20 and IEC 61340, demonstrate regulatory compliance, ensure audit readiness and maintain a safe, contamination-controlled environment for cleanroom operations.

While both ESD and anti-static flooring manage static electricity, they offer differing levels of protection.

Anti-static flooring: Reduces the generation of static. It’s good for general commercial or light industrial use.

ESD flooring: Controls, channels and grounds static completely. It’s essential for electronics manufacturing, labs, pharma, aerospace and precision assembly.

If downtime or component failure is an expense that your facility can’t risk, ESD flooring, not anti-static flooring, is the right solution.

In industries like electronics and pharmaceuticals, even a small disruption can cause immense problems. But with the right ESD flooring and safety measures in place, your facility can stay safe, productive and running smoothly for the long haul.

Static electricity may seem harmless, but in sensitive settings, it can destroy electronic components, corrupt data or cause equipment failure. In pharmaceutical environments, it may interfere with precision instruments, compromise sterile processes or even disrupt automated systems.

Uncontrolled static can lead to costly production delays, equipment downtime, product defects and safety risks for personnel. Something that no facility wants to risk. That’s why implementing ESD control measures, like specialized flooring, is absolutely key to protecting both equipment and operational reliability.

ESD flooring is essential in any environment that handles delicate electronics, precision instruments or contamination-sensitive processes. Common applications include:

ESD flooring can be sourced in a variety of materials, each with its own strengths. Vinyl, epoxy and rubber options all offer different levels of durability, comfort and static control, while conductive and dissipative systems provide more tailored protection against electrostatic discharge.

Selecting the right flooring ensures both safety and long-term performance for your facility.

These three types of ESD flooring give facilities the flexibility to pick the material that best suits their environment and workflow requirements:

Conductive and static-dissipative flooring systems operate on the same core principle: to control the movement of static electricity by providing a consistent, predictable pathway for it to safely travel to ground. Where they differ is in their level of electrical resistance.

Conductive flooring has a lower resistance, allowing static charges to flow quickly to ground, which is ideal for environments with highly sensitive electronics or explosive materials.

Static-dissipative flooring moves charges more slowly due to its higher resistance, which helps prevent sudden sparks.

Both control ESD, but the speed at which they move charge is what sets them apart. Choosing between them depends on industry requirements, sensitivity of the equipment being protected and the specific ESD performance standards a facility must meet.

For ESD flooring to work effectively, both installation and ongoing maintenance are vital. Proper installation ensures effective grounding and ongoing testing and maintenance keep the system performing at its peak

Installing ESD flooring isn’t just about laying down materials. It takes careful preparation and the right techniques. Subfloor conditions need to be checked to ensure the flooring bonds well and conducts electricity properly. Professional installers typically use grounding systems and conductive adhesives to guarantee compliance and reliable performance.

After installation is complete, the ESD floors must be routinely tested to confirm they still meet conductivity requirements. Facilities often use resistance meters or partner with certified inspectors to monitor performance.

Regular cleaning with approved, non-residue products also helps preserve the floor’s static control properties, as well as its durability.

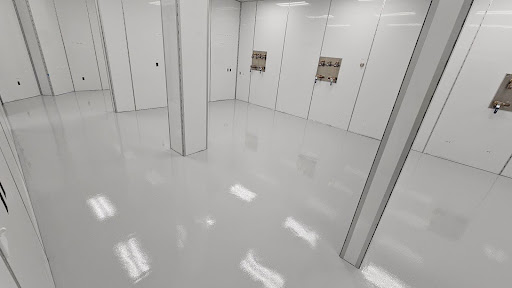

Protect your facility, equipment and operations with the right ESD flooring. At Black Bear Seamless Flooring, we craft and install conductive and static-dissipative floors designed to meet your facility’s exact needs.

Our experts are here to guide you in selecting the perfect materials and finishes to maximize safety, compliance and long-term performance. Discover the best ESD flooring solution for your project today!